If you're considering installing a metal roof, one of the most important factors to consider is screw placement. Proper screw placement is essential to ensure that your roof is secure, safe, and long-lasting.

In this article, we'll take a closer look at the basics of screw placement on metal roofs, including where to place screws and how to choose the suitable materials.

Metal roofing has become increasingly popular due to its durability, weather resistance, and structural integrity.

Metal roofs are made from various materials, including steel, aluminum, copper, and zinc. Each material has its unique properties and benefits.

One of the main advantages of metal roofing is its durability. Metal roofs can last 50 years or more, depending on the material and installation.

They are resistant to fire, rot, and insects, making them a popular choice for homeowners in harsh weather conditions.

Another advantage of metal roofing is its weather resistance. Metal roofs can withstand high winds, heavy rain, and snow.

They also resist hail damage, a common problem for traditional roofing materials like asphalt shingles.

In addition to their durability and weather resistance, metal roofs offer several other benefits. They are energy efficient, which can help reduce heating and cooling costs.

They reflect sunlight, which can keep your home cooler in the summer. They are also lightweight, which makes them easier to install and can reduce the load on your home's structure.

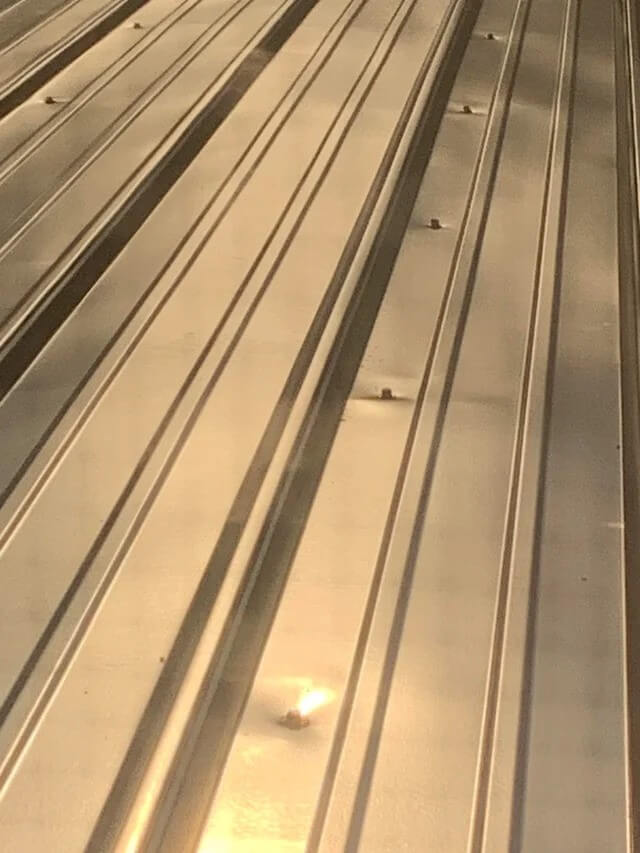

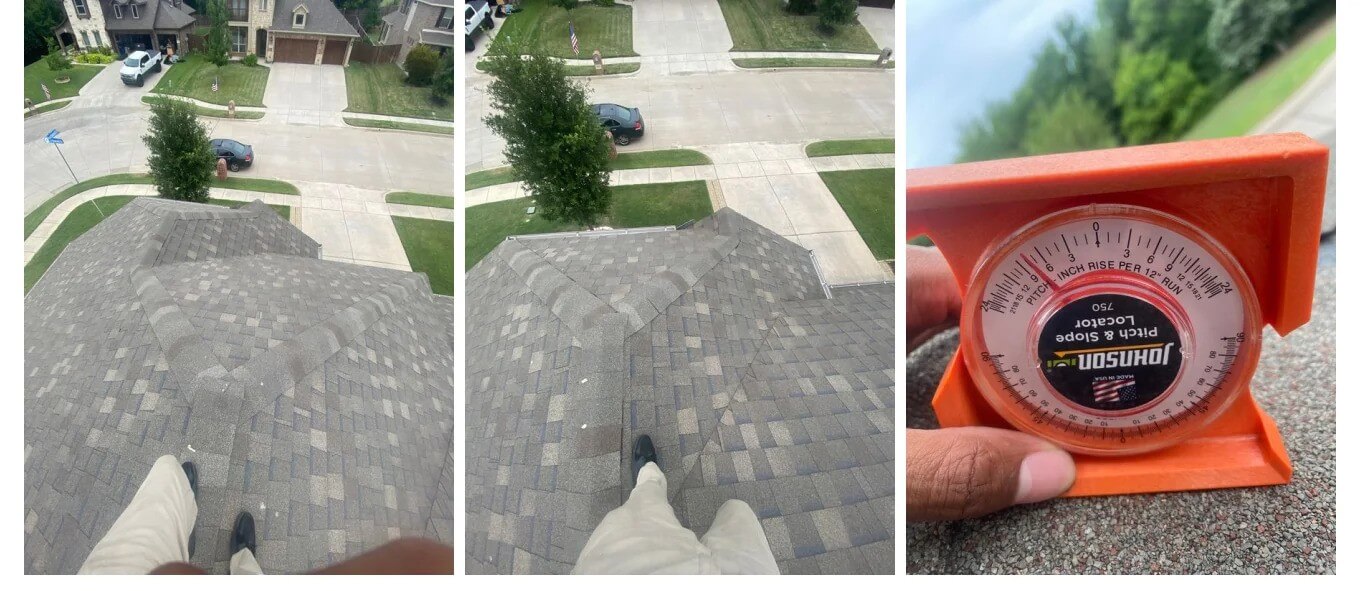

When it comes to screw placement on metal roofs, it is important to consider the type of metal roofing material, pitch or slope angle, weather conditions in your area, and local building codes.

Generally speaking, screws should be placed at every rib or corrugation for maximum support. Placing screws on the rib leaves a gap between the underside of the high rib and the wood framing below, which can negatively impact the sheer strength of the panels.

In conclusion, metal roofing is a durable, weather-resistant, and energy-efficient option for homeowners.

When installing a metal roof, it is important to consider the type of material and screw placement for maximum support and structural integrity.

When it comes to installing a metal roof, screw placement is a critical component that should not be overlooked.

Proper screw placement ensures that the roof is securely fastened to the structure, preventing leaks and other potential issues.

In this section, we'll cover some basic guidelines and spacing requirements for screw placement on metal roofing.

The placement of screws on a metal roof depends on several factors, including the type of metal roofing material, pitch or slope angle, weather conditions in your area, and local building codes.

Generally speaking, screws should be placed at every rib or corrugation for maximum support.

This ensures the roof is adequately anchored to the structure and can withstand high winds and other weather conditions.

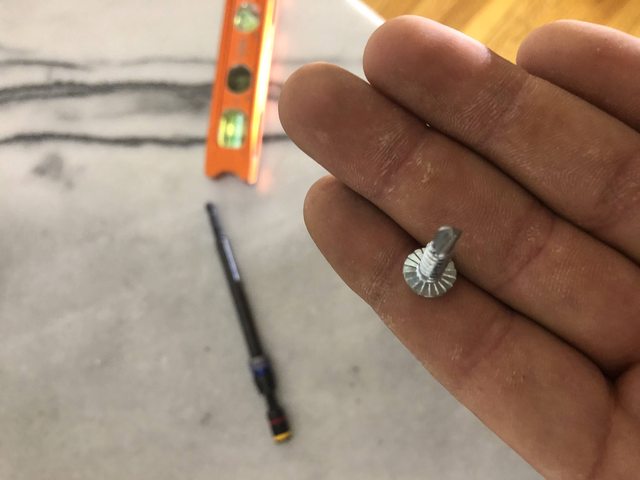

When installing metal roofing, it's also essential to use the correct type of screws and fasteners. Metal-to-wood screws, metal-to-metal screws, sealing tape, and lap screws are all commonly used in metal roofing installation.

Make sure to consult with your roofing manufacturer or contractor to determine the appropriate type of screws and fasteners for your specific installation.

Spacing requirements for screw placement on metal roofing can vary depending on the type of metal roofing material and the pitch or slope angle of the roof.

As a general rule, screws should be spaced no more than 24 inches apart along the length of the panel.

However, some metal roofing manufacturers may have specific spacing requirements that should be followed for optimal performance.

It's also essential to ensure that screws are not over-tightened or under-tightened during installation. Over-tightening screws can cause the metal roofing material to warp or buckle while under-tightening screws can result in leak points.

Use a torque wrench or other appropriate tool to ensure that screws are tightened to the manufacturer's recommended specifications.

Therefore, proper screw placement is essential for a successful metal roofing installation.

Follow the guidelines and spacing requirements outlined in this section, and consult with your roofing manufacturer or contractor if you have any questions or concerns.

When it comes to installing a metal roof, choosing suitable materials is crucial for ensuring the longevity and durability of your roof.

One of the most essential materials to consider is the type of screws that will be used to fasten the metal panels to the roof deck.

In this section, we will discuss the different types of metal roof screws and the factors to consider when selecting the correct fasteners.

There are several types of metal roof screws available on the market, each designed for specific applications. Some of the most common types include:

When selecting the correct fasteners for your metal roof, there are several factors to consider, including:

By selecting the right type of screws and fasteners for your metal roof, you can ensure a secure and long-lasting installation. Be sure to consult with a professional roofing contractor to determine the best materials and fasteners for your specific application.

When it comes to installing screws on a metal roof, there are a few techniques that can help ensure a successful installation. This section will cover two important techniques: pre-drilling and screw installation, and ensuring accurate placement.

Pre-drilling holes before installing screws is an essential step to avoid damaging the metal roof panels. Using the right tools is also essential to ensure the screws are correctly installed.

A drill with a metal bit is recommended for pre-drilling holes, and a screw gun with a clutch is recommended for installing screws.

When pre-drilling holes, make sure to use the correct size drill bit for the screws being used. This will prevent the screws from being too loose or too tight, which can cause damage to the panels.

After pre-drilling the holes, insert the screws into the holes and use the screw gun to tighten them. Be sure to stop the screw gun once the clutch engages to prevent over-tightening.

Proper screw placement is essential for the longevity and performance of a metal roof. The number of screws needed depends on the design of the metal panels and local building codes. On average, screw spacing should be between 12-24 inches apart, depending on panel length and thickness.

Perpendicular placement of screws is also essential to ensure the panels are correctly secured. Using a chalk line to mark the screw placement can help ensure accurate and consistent screw placement across the roof.

Therefore, pre-drilling holes and using the right tools, along with accurate and perpendicular screw placement, are essential techniques to ensure a successful installation of screws on a metal roof.

When it comes to preventing leaks on your metal roof, proper screw placement and sealing are crucial. Make sure to use the correct type of screws for your metal roof material, as using the wrong type can cause leaks.

For instance, if your roof is made of aluminum, then aluminum screws should be used. If the roof is made of steel, then steel screws should be used.

In addition to using suitable screws, it's essential to use washers that are designed to seal and waterproof the screw holes.

Rubber washers are commonly used for this purpose, as they provide a tight seal that prevents water from seeping through the screw holes.

To further prevent leaks, you can use sealants to seal around the screw heads and washers.

Silicone sealant is a popular choice, as it is durable and long-lasting. Apply the sealant around the screw heads and washers, making sure to cover the entire area to ensure a watertight seal.

Regular maintenance is also essential for preventing leaks on your metal roof. Inspect your roof periodically to ensure that the screws are tight and the washers are in good condition.

Loose screws and damaged washers can allow water to seep through the screw holes, causing leaks.

If you notice any loose screws or damaged washers, replace them immediately to prevent leaks from occurring.

It's also a good idea to clean your roof periodically to remove any debris that can clog the screw holes and prevent water from draining correctly.

By following these tips, you can prevent leaks on your metal roof and ensure that it provides long-lasting, leak-resistant protection for your home or business.

Metal roofing is famous for many homeowners due to its durability and longevity. However, improper installation can lead to leaks, damage, and other issues that can be costly.

Here are some common mistakes to avoid when installing screws on a metal roof and how to correct them.

One of the most common mistakes that people make when installing screws on a metal roof is over-tightening them.

Over-tightening can cause the screws to strip or create gaps between the panels, which can lead to leaks and other issues.

On the other hand, under-tightening can also cause problems, as the screws may not be able to hold the panels securely in place.

Another mistake to avoid is misalignment. When screws are not properly aligned, it can cause the panels to shift or buckle, which can lead to leaks and other issues.

It is essential to ensure that the screws are placed in the correct location and at the right angle to prevent misalignment.

If you have already made some installation errors, don't worry. There are ways to correct them.

For example, if you have over-tightened the screws, you can use a screwdriver to loosen them slightly until they are at the correct tension.

If you have misaligned the screws, you can remove them and reposition them in the correct location.

It is also essential to use the correct screws for your metal roof. Using the wrong type of screw can cause damage to the panels and lead to leaks and other issues.

Make sure to consult with a professional or refer to the manufacturer's guidelines to ensure that you are using the correct screws for your specific metal roof.

To prevent mistakes during installation, it is essential to take the time to prepare the roof deck properly and ensure that it is level and free of debris.

It is also essential to follow the manufacturer's guidelines for screw placement and spacing to ensure that the panels are securely fastened and will not shift or buckle over time.

By avoiding these common mistakes and taking the time to install screws on your metal roof properly, you can ensure that your roof will be durable, long-lasting, and free of leaks and other issues.

To ensure the longevity of your metal roof, it is essential to conduct routine inspections. The frequency of these inspections depends on your location and the weather conditions in your area.

We recommend inspecting your roof at least twice a year, preferably in the spring and fall.

During the inspection, check for any loose screws or fasteners, as well as any signs of wear and tear. Please pay close attention to the areas around chimneys, vents, and skylights, as they are prone to leaks.

Additionally, check for any debris or branches that may have fallen on the roof and clean them off.

If you notice any issues during your routine inspection, it is essential to address them promptly. Loose screws or fasteners should be tightened to ensure the roof's integrity.

If you notice any signs of wear and tear, such as rust or corrosion, replace the affected screws immediately.

If you notice any leaks or water damage, it is essential to identify the source of the problem. This may require a closer inspection or the help of a professional.

Once you have identified the issue, rectify it promptly to prevent further damage to your roof.

Regular maintenance and inspections are essential for the longevity of your metal roof. By following these guidelines, you can ensure the screw tightness and roof integrity and identify and rectify any issues before they become significant problems.

To summarize metal roof screw placement it is essential to remember essentials such as the type of roof you have, the distance for screw placement, selecting the correct fasteners, sealing and waterproofing.

Following the guidelines in this article will help you through this process of screws on your metal roofing.