Concrete removal is fundamental to construction, renovation, and demolition projects. It is absolutely necessary to ensure that concrete disposal and demolition are done through safe removal by employing efficient methods to eliminate concrete structures and surfaces.

Whether you're upgrading your property, clearing space for new construction, or addressing damaged concrete, it's essential to understand concrete removal and the different methods to dispose of concrete that can be undertaken.

In this article, we'll explore and walk you through the world of concrete removal and the methods for how to get rid of concrete effectively.

To undertake the task of concrete removal, it is essential to have the necessary skills and be highly committed to safety. Using the appropriate Personal Protective Equipment (PPE) is of absolute necessity among the paramount safety measures.

Let us now walk you through the critical importance of wearing PPE when engaged in concrete removal:

1. Protection from Flying Debris:

Effective gear like jackhammers and chisels are regularly used during concrete removal. These gear can generate flying particles and dust, posing a significant danger to your eyes, face, and skin. Safety goggles, face shields, and coveralls offer essential protection.

2. Respiratory Health:

When concrete is removed, tiny dust particles are created, which can be dangerous to breathe in. Your respiratory health is protected when you wear dust masks or respirators that are correctly fitted.

3. Hearing Protection:

Concrete-breaking machinery can make ear-piercing noises. Your ears are protected with earplugs or earmuffs, allowing you to work comfortably and securely.

4. Hand and Foot Safety:

Tools for removing concrete can be awkward, and severe hand and foot injuries are possible. Knee Pads, steel-toe boots, and sturdy gloves are all crucial protection against these potential risks.

5. Fall Prevention:

The possibility of falling exists when operating at heights or on uneven terrain. Safety harnesses and the proper fall protection equipment are essential in these circumstances.

6. Skin Protection:

You can be exposed to harsh substances and toxins if you remove concrete. Skin damage and chemical contact are avoided using gloves and long sleeves.

7. Compliance with Regulations:

The use of PPE in building and demolition activities, particularly the removal of concrete, is required by stringent rules in many locations. Compliance guarantees both legal observance and safety.

8. Personal Wellbeing:

Wearing PPE shows a dedication to personal wellbeing beyond legal obligations. It is a proactive measure to guarantee your safe return from work each day.

Concrete removal requires using the appropriate Personal Protective Equipment, which cannot be compromised. Protecting yourself against potentially life-altering accidents and health risks is a fundamental obligation, not just a matter of complying with the law.

Put safety first by donning the proper safety gear, and ensure everyone involved in removing concrete does the same. Successful concrete removal projects are founded on the pillar of your dedication to safety.

It is essential to thoroughly examine the work area before beginning any concrete removal project. This crucial stage guarantees the procedure's effectiveness and, more significantly, everyone's safety.

Here's a comprehensive guide on how to assess the work area for concrete removal, identify potential hazards, and plan the process accordingly:

1. Site Assessment:

Start by performing a thorough site assessment. This entails investigating the entire work area, including the concrete constructions, external setting, and entry points. Note any existing buildings, services, or obstructions that might impact the removal procedure.

2. Hazard Identification:

Pay great attention to possible dangers like:

Building Integrity Evaluate the concrete constructions' stability. Look for hazards that could arise during removal, such as cracks, weak spots, or degeneration.

Subterranean Services: Locate underground utilities, including gas, water, or electrical lines. If necessary, make contact with utility companies to precisely indicate their locations.

Environmental Issues: environmental elements such as adjacent water features, vegetation, and wildlife. Take action to prevent removal-related environmental damage.

Accessibility and Exit Ensure that personnel and equipment have safe Exit and entrance points. Determine any potential barriers or bottlenecks that might slow progress.

Weather: Keep an eye on the forecast, particularly for jobs completed outside. Weather-related problems can delay projects and jeopardize safety.

3. Regulatory Compliance:

Learn about the municipal, state, and federal regulations governing concrete removal. Ensure that your project meets all applicable environmental and safety regulations.

4. Safety Measures:

Make a complete safety plan with instructions for personal protective equipment, fall protection, first aid, and emergency procedures. Make sure to go over these safety measures with all relevant employees.

5. Equipment and Tools:

Check to see if the equipment and tools used to remove the concrete are adequate and in good shape. Check to see if they are up to code and maintained.

6. Contingency Planning:

Anticipate potential problems and be ready for them. This calls for having backup equipment, emergency action plans, and strategies for avoiding unforeseen threats.

7. Communication:

Create open channels of communication for the entire team. Ensure that each person is aware of their duties and emergency contact information.

8. Documentation:

Maintain thorough records of the necessary permissions, the site appraisal, the identification of hazards, and the safety plans. Documentation is necessary for accountability and compliance.

9. Review and Revise:

Review and revise your removal and safety strategies as the project progresses. Consider lessons learned and adjust to changing conditions for continued development.

By following these steps, you enhance the safety of your concrete removal project and streamline the process for efficiency. Remember that meticulous planning and hazard identification are integral to a successful, incident-free concrete removal endeavor.

In construction and remodeling projects, breaking and removing concrete is common. Whether repairing cracked concrete, laying a new foundation, or demolishing an old structure, the procedure calls for accuracy, safety, and efficiency.

Here's a how-to for breaking concrete with jackhammers and taking out the fractured pieces for disposal:

1. Safety measures:

2. Equipment Setup:

3. Concrete Breaking:

4. Removing Broken Concrete:

5. Site Cleanup:

6. Maintenance and Safety:

Concrete removal and breaking calls for accuracy and respect to safety procedures. By following this step-by-step manual, you may effectively and safely execute concrete demolition projects while lowering worker and environment risks.

Concrete can be cut into manageable bits for disposal in a controlled and exact manner. Understanding this method is crucial if you're working on building, remodeling, or destruction.

Here's a comprehensive guide on how to cut concrete using saws or specialized equipment:

1. Safety Precautions:

2. Equipment Selection:

3. Concrete Cutting:

4. Removing Cut Concrete:

5. Site Cleanup:

6. Maintenance and Safety:

Large-scale concrete excavation, such as that needed for foundations or slabs, calls for powerful machinery and meticulous design. Whether for site preparation, renovation, or building, the procedure entails particular measures to guarantee effectiveness and safety.

Let's delve into the process of excavating large concrete areas using heavy equipment:

1. Site Preparation:

2. Equipment Selection:

3. Concrete Cutting (if necessary):

4. Excavation Process:

Excavate to the necessary depth while carefully not damaging any underlying utilities or structures.

5. Removing Excavated Concrete:

6. Site Cleanup:

7. Maintenance and Safety:

Safety must always come first when excavating huge concrete areas because it is a significant operation. This method can safely and effectively remove concrete slabs or foundations with heavy machinery while reducing hazards for the environment and the personnel.

Concrete recycling is an environmentally responsible practice that minimizes waste and offers numerous benefits for construction and landscaping projects.

Let's explore the advantages of recycling concrete waste and utilizing it for various purposes:

1. Environmental Sustainability:

2. Cost Savings:

3. Versatile Applications:

5. Environmental Impact Reduction:

6. LEED Certification:

7. Community Benefits:

8. By eliminating waste and reusing valuable resources, employing recycled materials like concrete in construction projects helps to advance the circular economy.

Recycling and reusing concrete waste offer many benefits, including environmental sustainability, cost savings, versatile applications, and structural Integrity.

By incorporating recycled concrete into building and landscaping projects, we support the ideas of a circular economy and help to make waste management more environmentally friendly and sustainable.

Compliance with local laws is essential, but responsible concrete disposal also involves a dedication to environmental stewardship and sustainable techniques.

We can reduce the environmental impact of removing concrete by choosing appropriate facilities and adhering to correct disposal requirements.

Here's why responsible concrete disposal matters and how to achieve it:

1. Environmental Stewardship:

Conserve Natural Resources: By lowering the demand for fresh aggregates and reducing the ecological impact of concrete removal, responsible disposal contributes to preserving natural resources.

2. Compliance with Local Regulations:

Legal Obligations: Compliance with regional building and waste management regulations is required. Non-compliance can result in expensive fines, penalties, and damage to your reputation.

3. Pollution Prevention:

Reduce Environmental Damage: By disposing of concrete debris properly, ecosystems and public health are protected from contamination of soil and water sources.

4. Sustainable Practices:

Promote sustainability: By reusing and recycling materials, responsible disposal methods support the idea of a circular economy and align with larger sustainability aims.

5. Reduction of Construction Waste:

Reduce garbage: Careful disposal reduces the amount of garbage dumped in landfills, relieving pressure on these facilities and extending their useful lives.

6. Public Image and Reputation:

Community Relations: Making an effort to dispose of waste responsibly builds your company's reputation and encourages goodwill in the neighborhood.

7. How to Achieve Responsible Concrete Disposal:

Consult local authorities: Recognize and abide by any municipal rules governing the removal and disposal of concrete. If required, seek advice from neighborhood environmental organizations.

Select only accredited facilities: For concrete disposal, choose facilities with the necessary licenses and licenses. These facilities follow environmental best practices and laws.

Look into recycling opportunities or reuse concrete waste in building or landscaping projects when possible.

Document Conformity: Keep track of all concrete disposal activities, including waste manifests and verification of disposal facility permits.

Educate Employees: Ensure everyone participating in concrete removal is informed on ethical disposal methods and environmental concerns.

Consider alternate strategies: Investigate less-expensive alternatives to conventional disposal, such as on-site concrete crushing and recycling, which can lessen the need for disposal facilities.

Responsible concrete disposal is an integral part of sustainable construction practices. By adhering to local regulations, selecting appropriate disposal facilities, and embracing environmentally sound removal methods, we can contribute to a cleaner and more sustainable environment while upholding our legal and ethical obligations.

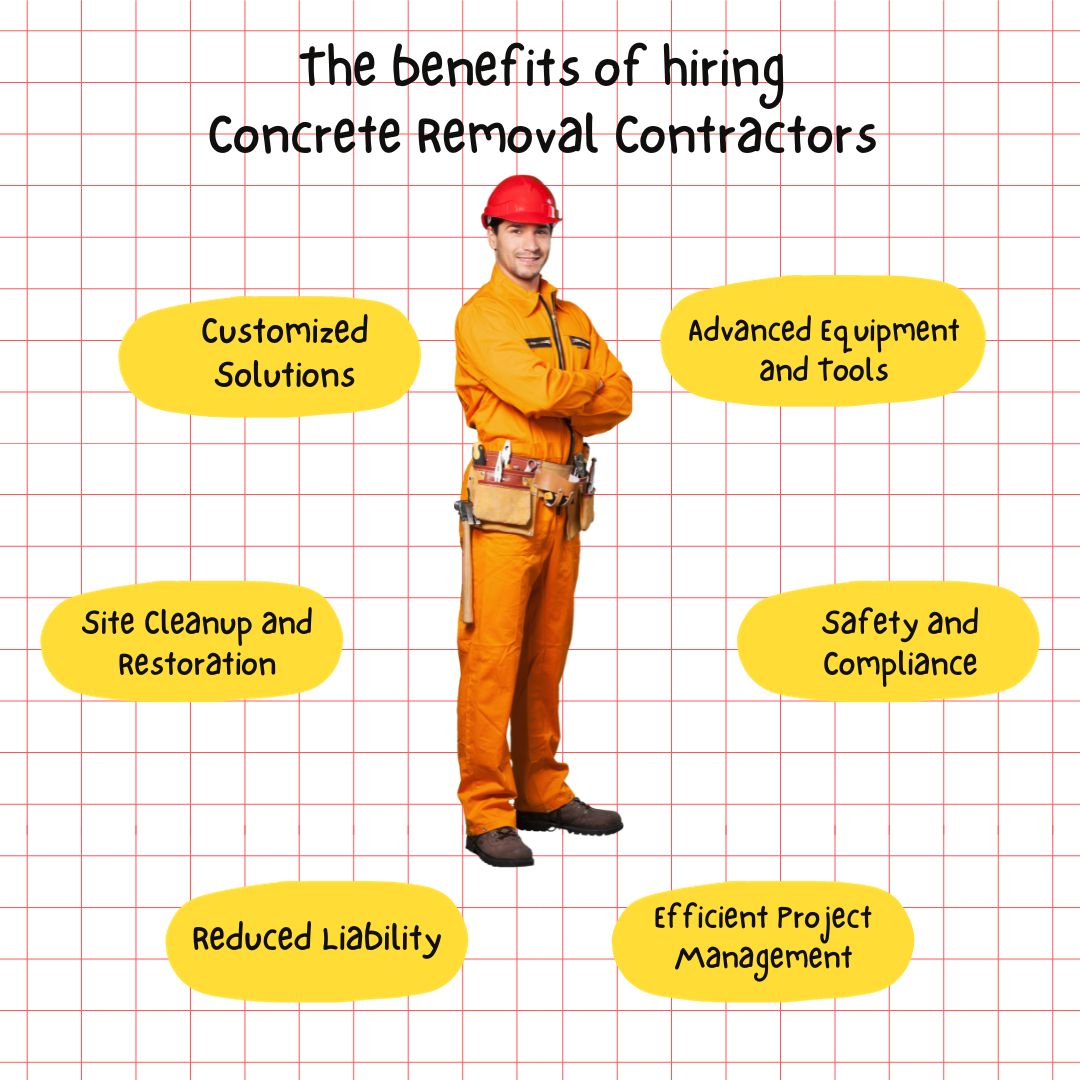

Hiring a competent concrete removal contractor's services for large or complicated concrete removal jobs has many benefits.

These knowledgeable specialists are valuable for projects that call for accuracy, safety, and efficiency since they bring much knowledge and expertise.

Here are the key benefits of hiring concrete removal contractors:

1. Specific Knowledge:

2. Advanced Equipment and Tools:

3. Safety and Compliance:

4. Efficient Project Management:

5. Customized Solutions:

7. Reduced Liability:

8. Quality Assurance:

9. Site Cleanup and Restoration:

In conclusion, there are several advantages to using professional concrete removal companies for large or complicated tasks, including knowledge, cutting-edge technology, safety, effectiveness, and peace of mind.

They are crucial partners for ensuring the smooth completion of challenging concrete removal projects because of their capacity to accurately undertake sophisticated demolition jobs.

Let us go through a concrete removal recap: there are several methods for getting rid of concrete, each suited to specific project needs. It's crucial to emphasize the importance of safety and eco-friendly disposal throughout the concrete removal process.

Some final takeaways and thoughts on concrete disposal that are important for you to understand are as follows: through keeping safety first, using eco-friendly disposal, on-site recycling and responsible practices in concrete removal projects you can achieve efficient and responsible results.